Eddy current testing (ET) method is suitable for detection of surface and subsurface defects. This method is more accurate than magnetic particle testing or dye penetrant testing methods.Last two methods in most cases can be successfully replaced by eddy current method.

Defects detected: surface cracks, surface LOFs, inclusions, heat exchangers tubes metal loss due wear or erosion (corrosion), others surface and subsurface defects and discontinuities.

We are performing eddy current testing of heat exchangers tubes (both ferrite and non-ferrite), turbine blades, welded joints and parent material (for surface and subsurface defects).

|

Eddy current methods also is used for metal sorting and non-conductive surface coatings thickness determination.

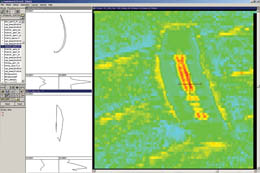

Surface crack detected using

automated ET system TC 5700

Following flaw detectors are used: Phasec 3D (GE Inspection Technologies), ELOTEST B1 (Rothmans), MIZ-40 RFT (Zetec), MIZ-20 (Zetec) ir TC5700 (Zetec).

Test can be performed manually, semi-automated or automated (using standard general purpose manipulators or scanners). Complete ET data are recorded when semi-automated or automated ET is being performed (for more details see UT chapter)

ET standards: LST EN ISO 15549:2011, LST EN ISO 17643:2016.

Certified personnel: 1 specialist level 3 and 14 ET level 2 specialists certified according to LST EN ISO 9712 and Nordtest.