DEKRA Industrial experience and personnel

DEKRA Industrial has large experience of Inspection services in the nuclear industry. Its personnel has up to 25 years experience.

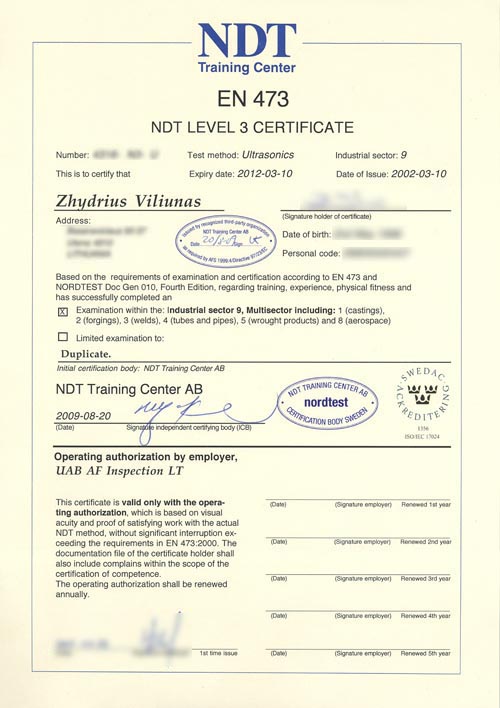

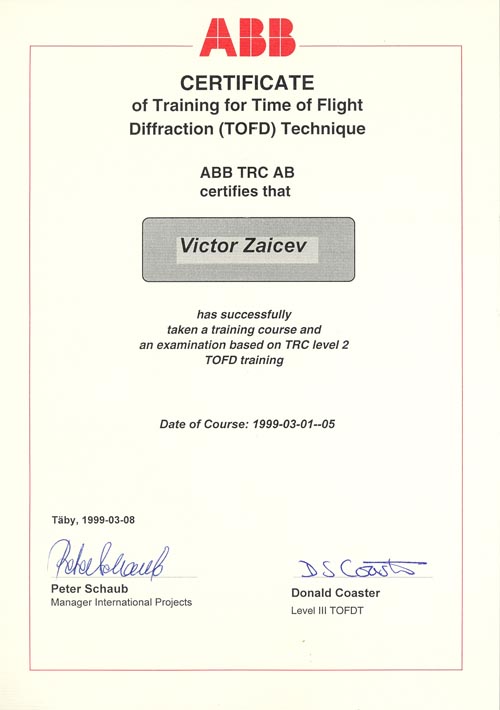

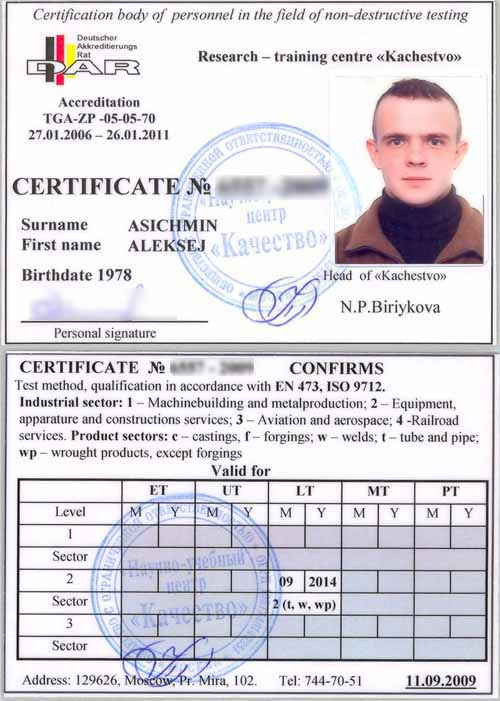

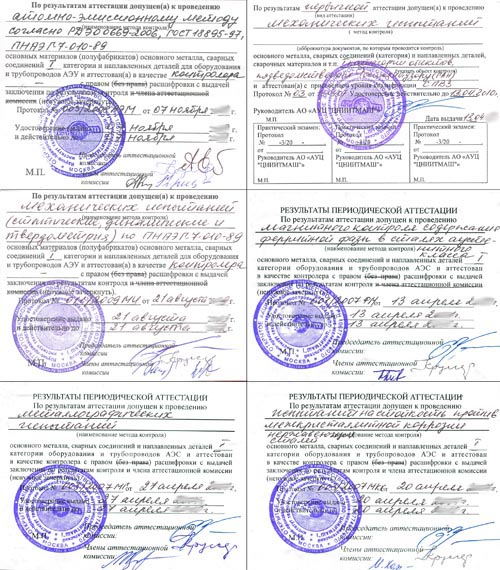

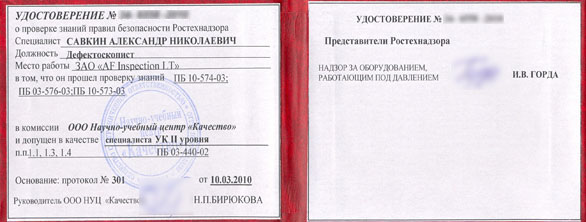

DEKRA Industrial NDT personnel has been successfully trained and certified with at least level 2 in accordance PNAEG (standards and norms of nuclear power engineering), PB 03-440-02, EN 473 and EN 473/Nordtest (Sweden) in the following NDT methods: ultrasonic testing (UT), eddy current testing (ET), visual testing (VT), radiography (RT), penetrant testing (PT), magnetic particle testing (MT) and leak testing (LT).

DEKRA Industrial personnel performing material investigation were trained and certified in leading Russian Material science centers (CRISM “Prometey” (St. Petersburg), CNIITMASh (Moscow) and others).

DEKRA Industrial has long experience in providing material investigation services by means of Mechanical tests (tensile tests (normal and elevated temperature), Charpy impact tests, Static bending tests, Flattening tests, Hardness tests); Metallography (Micro and Macro structure), Resistance to Inter-granular corrosion in stainless steel, Delta ferrite content in austenitic weld material; Chemical content definition (Spectrum analysis).